Keys To Selecting Dewatering Liner Materials

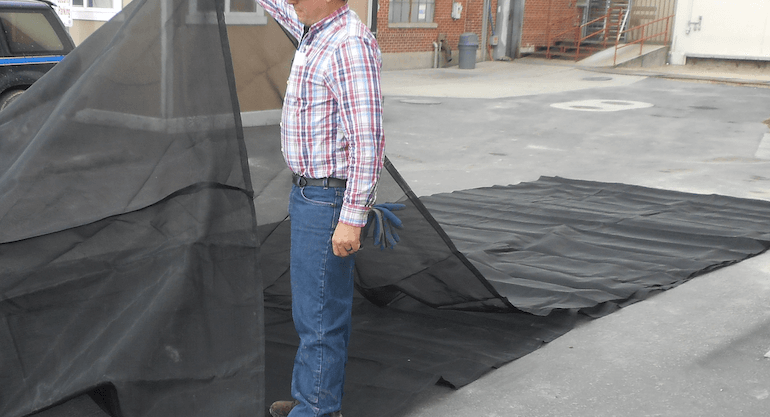

Drainable Container Box Filter Liners or Bags Used In Dewatering Operations

Utilizing the technological advantages of screen and non-woven polypropylene materials, dewatering liners are an effective avenue for draining liquids from sludges while leaving solids for disposal or other uses.

Ideal for use with standard and specialized steel dewatering containers fitted with dewatering liner screens or welded in perforated steel for the most efficient flow through of liquids through the liner and screens and out of the container. Critical Point: Without these screen features, the sludges/materials/liquids may blind the liner off and flow is restricted. See Link At Bottom Of Page For Views of Dewatering Containers.

The selection of the right dewatering container liner material for your application can often be a puzzle with sludges of all types requiring different liner bag materials.

Key Questions

- What Micron Rating Do You Require? Below You Will Find Links To Technical Data Regarding Particle Sizes And Micron Ratings.

- What is the Size (dimensions) Of the Container Box? Important Detail To Size The Right Liner To the Container Box?

- Will The Filter Liner Be Used In A Container With Inside Or Outside Hooks?

- What are your expectations of time and drainage performance?

- Does your container have a side to side or end to end barrier inside the container. That feature would require a different style or configured liner.

- Do you have time for us to send out a test kit for your operation to evaluate the best material and micron selection?

When you call or email us, we’ll offer additional details and ask questions to get to how best to serve your specific application.

Particle size ranges converted to microns hold the key to dewatering filtration.

Particle size characteristics

Particle Mesh and micron conversions

We ask a lot of questions about your requirements. If it will help, after speaking about the specifics of your application, the next step may be to test and evaluate sample materials on-site at your facility or field operation.

Material and Liner Examples

CIU-20-30yd-3.5oz Universal 3.5oz NWPP Cloth Filter Bag Used in 20-30 yd. Standard or Turbo Dewatering Containers(~130 micron) This is the most commonly purchased dewatering container liner/bag.

Other commonly used Dewatering-Filtration Liners

- CIU-20-30ydSM Universal Screen Mesh Filter Bag for Standard or Turbo 20-30 yd. Dewatering Containers (250 micron)

- CIU-20-30ydKM Universal Knit Mesh Filter Bag for Standard or Turbo 20-30 yd. Dewatering Containers(400 micron)

- CIU-20-25yd-CT- 4oz NWPP Cloth Filter Bag Used in 20-25 yd. Standard Dewatering Containers(~100-115 micron)

- CIU-20-30yd-4oz Universal 4 oz NWPP Cloth Filter Bag Used in 20-30 yd. Standard or Turbo Dewatering Containers(~100-115 micron)

- CIU-20-25yd-CT- 6oz6oz NWPP Cloth Filter Bag Used in 20-25 yd. Standard Dewatering Containers(~80-100 micron)

- CIU-20-30yd-6oz Universal 4 oz NWPP Cloth Filter Bag Used in 20-30 yd. Standard or Turbo Dewatering Containers(~80-100 micron)

- CIU-20-25yd-CT-3.5oz 3.5oz NWPP Cloth Filter Bag Used in 20-25 yd. Dewatering Containers “130 micron”

- CIU-20-25yd-CT-SM Description: Screen Mesh Filter Bag for Standard 20-25 yd. Dewatering Containers “250 micron”

- CIU-20-25yd-CT-KM Knit Mesh Filter Bag for Standard 20-25 yd. Dewatering Containers “400 micron”

Additional Technical Details Available On Request

View Main Dewatering Liners Technical Page

Dewatering | Sediment Bags – Technical Details

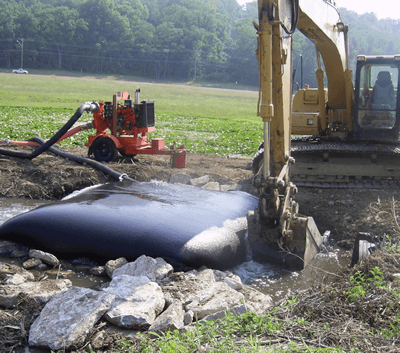

Dewatering Bags are designed to filter sediment, silt, and sludges by discharging water while containing the suspended solids inside of an on-site, small footprint, dewatering bag.

Dewatering Bags are designed to filter sediment, silt, and sludges by discharging water while containing the suspended solids inside of an on-site, small footprint, dewatering bag.

Dewatering bags use inward pressure to provide enclosed dewatering without the need of a support container.

Standard and Custom Bags Available In A Very Broad Variety Of Sizes And Materials. Bags shown below are examples of larger selections.

Broad selections of fabric material options.

General Details

Flow/dewatering rates will vary dramatically according to soil type.

Sand will typically flow/dewater at the fastest rate with clay flowing the slowest.

-Wet sand weighs approx 120 lbs per cu/ft

Clay can also blind over the fabric in some instances blocking flow entirely.

Clean fabric will flow as follows:

Standard Dewatering Bag @ 90 gpm per sq ft

Reusable Dewatering Bag @ 50 gpm per sq ft

Dewatering Bags are normally allowed to dry in place then cut open and spread/removed with heavy equipment.

TYPICAL APPLICATIONS

Municipal wastewater

Industrial pond pumping and dredging

Agricultural waste pumping and dredging

Waterway remediation and dredging

Power plant cooling tower sludge

Construction and plant turnaround projects

FEATURES

Dewaters without a container

Provides waste volume reduction

Utilizes internal pressure to dewater

Assists in cleaning contaminants from water

Enables dewatering for hard to access areas

Accommodates up to 8″ diameter discharge hose

Contains solids for disposal

Stock and custom sizes available

Bag Examples

Dewatering Bag 6’ x 6’ x 1′ holds approx 36 cu ft (1.3 cubic yds)

Dewatering Bag 6’ x 6’ x 1′ holds approx 36 cu ft (1.3 cubic yds)

– Total weight full approx 4320 lbs.

Dewatering Bag 10’ x 15’ holds approx 150 cu ft (5.6 cubic yds)

– Total weight full approx. 18,000 lbs.

Dewatering Bag 15′ X 15′ holds approx 225 cu ft (8.3 cubic yds)

– Total weight full approx 27,000 lbs.

Reusable Dewatering Bag 3’ x 5’ x 1′ holds approx 15 cu ft (0.5 cubic yds)

– Total weight full approx 1800 lbs.

– Reusable Dewatering Bags can be emptied and reused.

Reusable Dewatering Bag 5’ x 7’ x 1′ holds approx 35 cu ft (1.3 cubic yds)

– Total weight full approx 4200 lbs.

All bags are typically in inventory. Please call for delivery times and availability.

Dewater FIBC

Dewatering | Drainable Bulk Bags

An economical addition for facility and field dewatering and drainable applications. This has become a viable and useful product in many projects where compact drainable fabrics are the right solution. It’s recommended that industrial operations test and evaluate for demanding specific application performance.

Additional Technical Details Available On Request

P.O. Box 8149

P.O. Box 8149