Liquid Dispensing Solutions

Important dispensing details

When dispensing, air must enter the container to prevent a vacuum. If a vent is not present, the vacuum will be relieved through the emerging liquid stream and will create a turbulent, splashing flow. Also, because liquids expand as their temperatures increase, some form of pressure relief is needed to prevent leakage or drum (container). Rupture can be caused by excessive pressure buildup in the closed drum or container.

Drum vents, or safety bungs, provide both vacuum and pressure relief. The flammable liquid vapors are released and a flame-arresting screen or perforated plate prevents flames from traveling into the drum itself.

For safe storage practices of flammable/combustible liquids, please refer to:

- NFPA Standard 30, Flammable and Combustible Liquids Code

- NFPA Standard 77, Static Electricity

Handling and dispensing of flammable and combustible liquids

The entire range of industrial operations from manufacturers to field operations to repair facilities and a whole host of other businesses that need to store and dispense flammable or combustible liquids require numerous layers of liquid handling considerations. Dispensing of flammable liquids from original containers for mixing or transfer creates an exposure to losses. Dispensing such materials may produce flammable vapors, leaks and spills that could ignite. To prevent fire or explosion, the storage and dispensing of flammable/ combustible liquids must be done properly. Chemicals that also may be chemically incompatible will require additional safe storage and handling planning.

Procedures

The preferred method for dispensing Class I and Class II liquids (flashpoints under 140°F) from shipping or storage containers to smaller receptacles may be accomplished using one of the following methods:

- Drawing through the top of the container using a UL listed/FM approved transfer pump and into an approved safety container. This is the preferred method of dispensing from a drum since the vertical arrangement minimizes the possibility of leaks or spills.

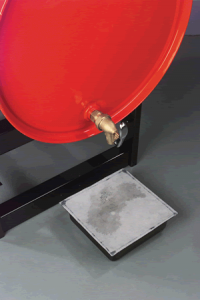

- By gravity through a UL listed/FM approved self-closing faucets or valves, usually from drums. Listed and approved valves will have a flame arrestor built-in to prevent ignition of the container’s contents from outside ignition sources.

- A bung vent on the drum is also needed.

- A listed drip pan with a flame arrestor should be located under the faucet to catch minor leaks and spills

- Pouring from the original container with a capacity of five gallons or less

- Pouring from safety cans used as storage containers

Contact us about our complete range of drum and pail handling equipment.

Static electricity

Dispensing and spill capture.

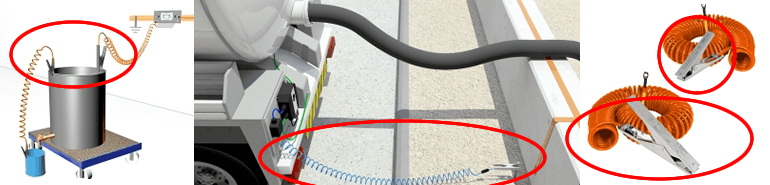

Static charges may be generated any time flammable liquids move through a conduit such as piping or hose. Charges may also be generated when those liquids are mixed, poured or pumped. If the amount of static generated is sufficient, a static spark may be generated and may ignite flammable vapors. Therefore, static electricity must be controlled by bonding and grounding.

Critical Bonding and Grounding Basics

Bonding is the process of connecting conductive objects together using an electrical wire. When flammable liquids are dispensed from one conductive container into another, a bonding cable must be used to make an electrical connection between the containers. This is done so that both containers reach the same electrical potential, and remain at that potential. Grounding is the process of connecting two or more conductive objects to earth. When properly grounded, a static charge is dissipated as fast as it is generated. Grounded objects reach the same electrical potential as the earth and are therefore electrically neutral. Any container that will be dispensed from should be grounded at all times.

Flammable liquids are usually dispensed from metal containers into other metal containers. Each container being filled should be bonded to the dispensing container. There are two means to do so. The container to be filled may be bonded directly to the dispensing container. Alternately, the container to be filled may be bonded directly to the Flammable liquids are usually dispensed from metal containers into other metal containers. Each container being filled should be bonded to the dispensing container. There are two means to do so. The container to be filled may be bonded directly to the dispensing container. Alternately, the container to be filled may be bonded directly to the earth ground to which the dispensing container is also connected. Either method results in a good bond and minimizes differences in electrical potential between containers.

Different precautions should be taken when a plastic or glass container is involved in dispensing. This is important whether the original container or the filled container is nonmetallic, or both. A grounded lance should be placed into the container being filled so it will reach the bottom. A grounded band surrounding the container should be used to reduce the static field on the surface of the liquid. Any metal objects near the container should be grounded as they could become charged by induction.

Different precautions should be taken when a plastic or glass container is involved in dispensing. This is important whether the original container or the filled container is nonmetallic, or both. A grounded lance should be placed into the container being filled so it will reach the bottom. A grounded band surrounding the container should be used to reduce the static field on the surface of the liquid. Any metal objects near the container should be grounded as they could become charged by induction.

There are broad ranges of grounding and bonding products specifically designed for a very extensive range of uses and applications. Some of those include:

- Grounding clamps on cables

- Grounding clamps on reels

- Alternative grounding assemblies

- Personnel grounding

Secure Storage For Liquid Handling

Drum dispensing and spill control

The size of conductors used for bonding and grounding is determined by the need for mechanical strength rather than by the electrical resistance required. The resistance of a ground does not need to be less than one megohm. Two good grounding sources are cold water pipes upstream from the meter and driven grounding rods.

Proper connections in the grounding and bonding system are important. A permanent connection should be made on the earth end of the ground cable. There are several means to accomplish a good connection on the container side. Strong alligator or battery type clamps can be used, as long as the connection penetrates the containers’ coatings (painted surface) to ensure metal-to-metal contact. A better means is to use point clamps, which penetrate container coatings.

The size of containers being dispensed from or filled does not have an effect on whether static charges may accumulate. It is always a best practice to provide grounding and bonding. However, very small containers, 1 gallon or less, may be exempted from these guidelines. The potential fire ignited by stray static is not as likely to be severe since the quantity of liquid involved is limited.

No matter what kind of storage is being used, if there’s a chance of flammability or combustiblity, always contingency plan for worst case scenario.

Container Storage Rack Spill Capture

Capture leaks and spills below pallet or racking. Industrial racking (steel racking, pallet racks, etc) is important for liquid storage and dispensing. They are the shelving units of the industrial world. So it only stands to reason that there will be some applications where liquid (or other materials that might leak or spill) is stored on racking.

Capture leaks and spills below pallet or racking. Industrial racking (steel racking, pallet racks, etc) is important for liquid storage and dispensing. They are the shelving units of the industrial world. So it only stands to reason that there will be some applications where liquid (or other materials that might leak or spill) is stored on racking.

For those situations, our Rack Spill Trays can be easily slid beneath the bottom shelf and used to capture small leaks, drips and spills. One, two and three tray systems are available to fit a number of different widths and the optional connector allows units to be connected to make any size system needed.

Key Features:

Low-profile ( 2 3/4”) spill trays slide easily under pallet racking and shelving.

- Small leaks and spills from palletized contents above are captured — keeping floors clean and free from slip hazards.

- Black, all-polyethylene construction provides excellent chemical compatibility and corrosion resistance

- Three tray systems available to fit any size rack or shelf. Contact us to learn more

- Additional trays and/or connectors may be added for larger applications or revised configurations.

- Warranty: Protected by the industry’s strongest warranty – Five (5) years.

P.O. Box 8149

P.O. Box 8149